With know-how gained in various sectors, and the automotive sector in particular, GN Engineering provides full client support from the design feasibility study through to the final production of products and components.

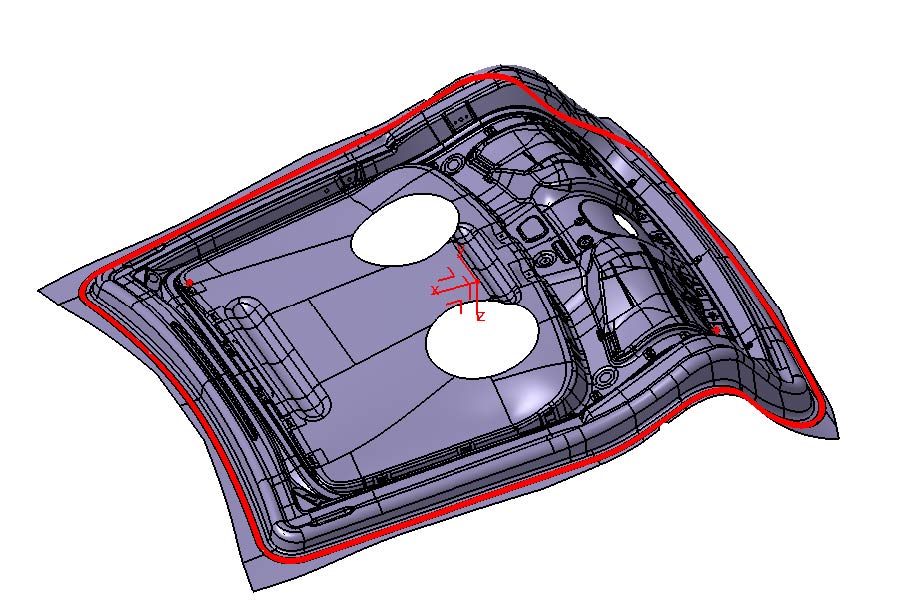

The feasibility phase entails project analysis and the proposal of solutions and improvements. Cutting-edge software tools allow us to produce feasibility studies that highlight critical item features (thinning, tendency to pucker, buckle, etc.) and propose solutions and modifications to make the process safe and repeatable.

GN Engineering identifies the product development method based on the feasibility study and uses simulations to refine the entire production process and make it more robust.

The purpose of this operational phase is to identify possible issues that could hinder the manufacturing process in advance. Accurate simulation software allows critical issues to be identified thus allowing production to proceed while minimising errors and optimising mould production times. In-depth review of the work cycle, validated by the simulation and backed by critical analysis of the results allows us to provide a solution based on optimised die production time optimisation in the workshop that anticipates any issues that may arise with regard to process stability and wearing of the sheet metal.

In order to reduce set-up times, we are able to provide analysis of springbacks vitiated by the tools and supporting information such as the optimal geometry of the edges.

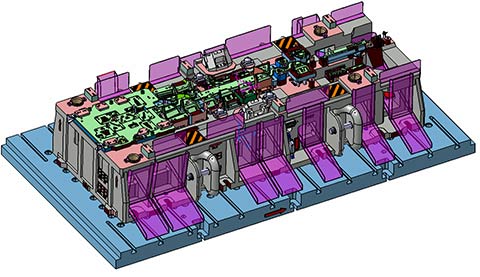

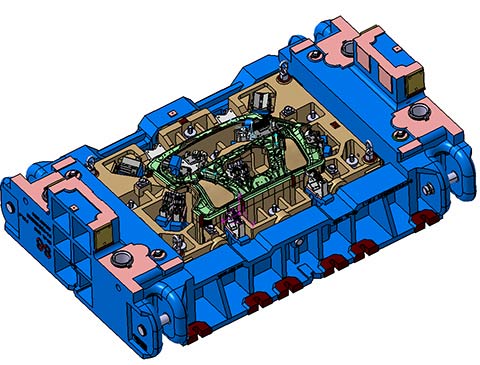

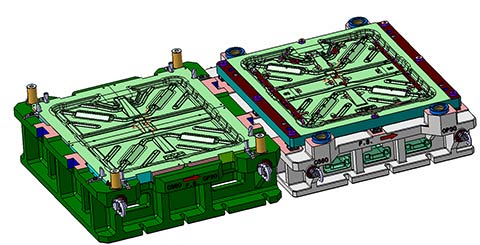

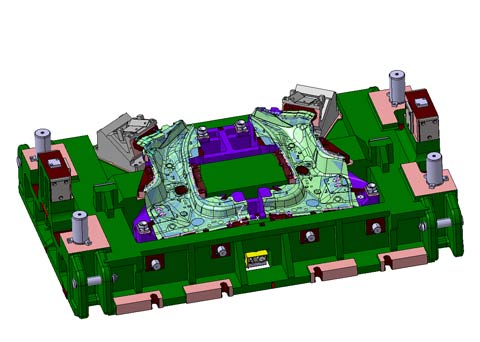

The GN Engineering team design dies entirely in CAD 3D, while taking into all client requests into consideration and using reference specifications. Thanks to our experience, gained primarily in the automotive sector, we are able to design any type of die.

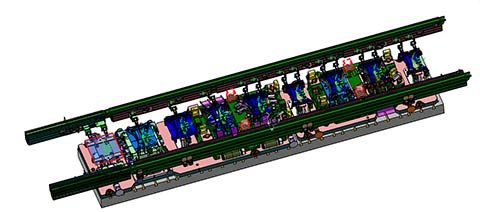

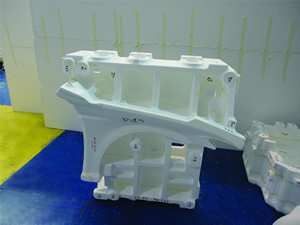

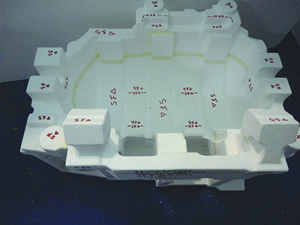

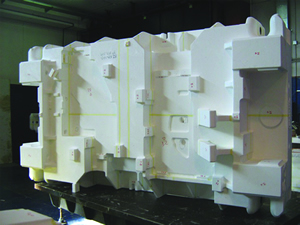

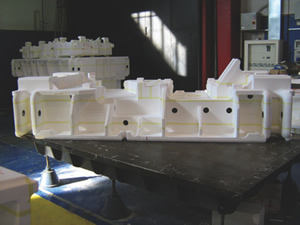

GN Engineering constructs polystyrene and/or polyurethane demo models and produces polystyrene for use in foundries. Our workshops are equipped with CNC milling machines that allow us to produce models of any size and complexity.

Toolpaths

Advice during the feasibility and press die spotting phase

Presentation at client premises on your behalf

GN Engineering

Piazzale Europa, 7 – 10044 Pianezza (TO) Italy – Tel/Fax +39 011.79.11.167

amministrazione@gnengineering.it